In the world of micro-machining, the Citizen R-series sets the bar. The R04 and R07 run sub-4mm and sub-7mm stock for the tiny parts the medical and tech industries now prize. These Swiss lathes pack ultra-high-speed spindles into a compact footprint, delivering the thermal stability you need for these tight tolerances.

However, this attribute that makes these machines so effective—their compact design—creates a significant setup challenge. The work envelope is incredibly confined, and the tooling layout is dense. This lack of accessibility often forces operators to rely on "best guesses" rather than verified X and Y axis alignments, simply because traditional alignment tools cannot easily fit, and the naked eye cannot see the contact point clearly.

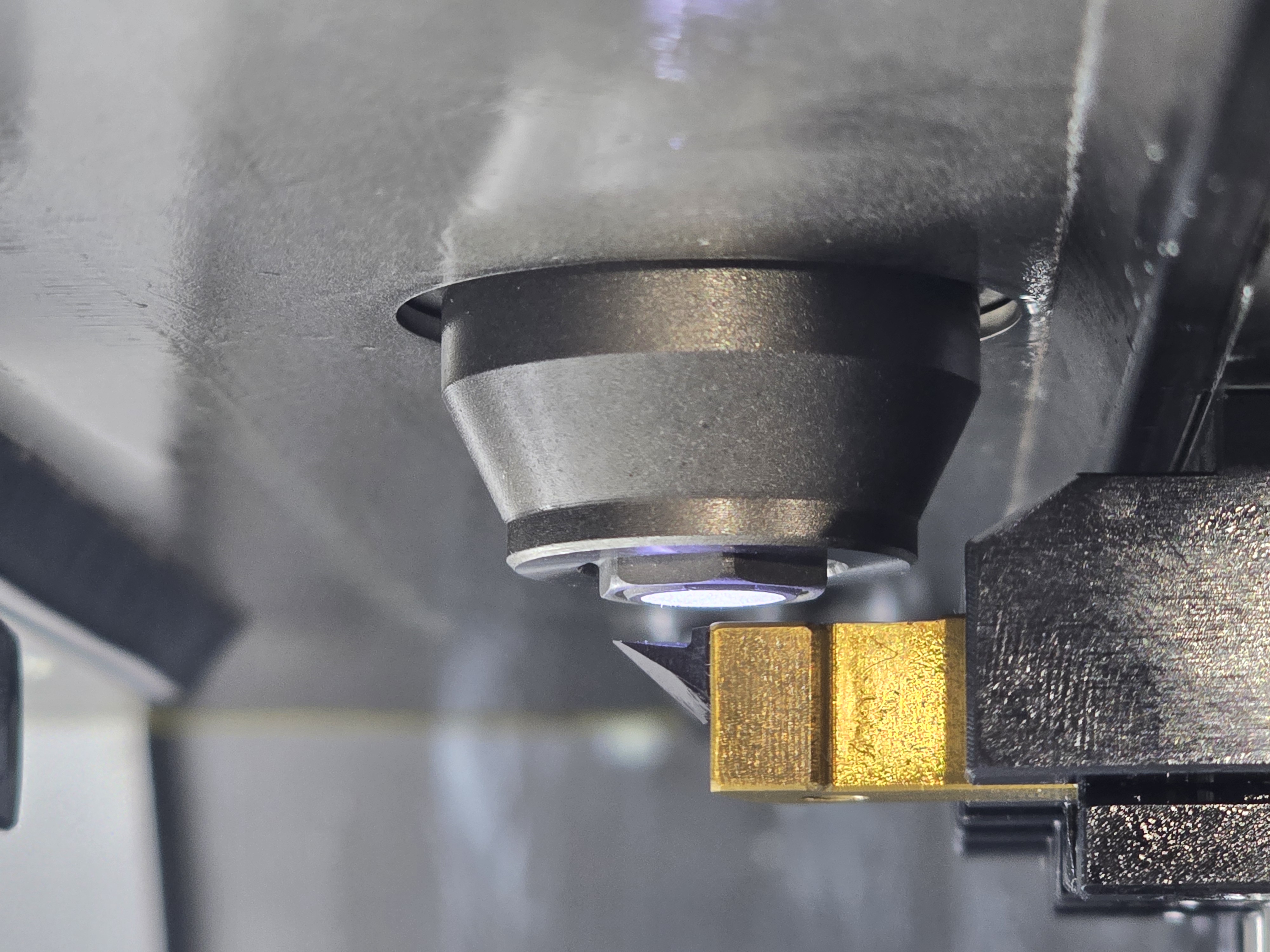

Introducing Our Smallest Perfect Zero® Camera to Date

We've engineered a solution to bridge this visibility gap.

Meet the Perfect Zero® alignment cameras for the Citizen R04 and R07. They represent our smallest fit diameters to date, purpose-built to slide directly into the PD4 (R04) or TD7 (R07) guide bushing assembly.

Stop Guessing. Start Seeing.

The biggest challenge with these Swiss machines isn't the cutting capability; it's the variables. When a process fails on a micro-part, finding the root cause is often a game of trial and error. Is the tool off-center? Is there runout? Is the tool worn or chipped?

Until now, it was hard to know without running parts and measuring the failures.

With our new cameras, just open up your laptop and…

- Know exactly where a tool's cutting edge is in relation to the center of the spindle.

- Quickly align tools and set offsets with our guided software.

- Eliminate the guesswork of why a process is failing.

- Uncover the root cause of a problem once your tools are aligned.

Whether you are running the R04 with its PD4 guide bushing or the R07 with the TD7, our new cameras grant you visibility that was previously impossible in such a confined work envelope.

Don't let the size of the machine dictate the size of your headache. Use our smallest Perfect Zero® guide bushing and sub spindle cameras, align your tools to the centerline, and let your process run.