Want faster setups? Better tool life? Repeatable cost savings?

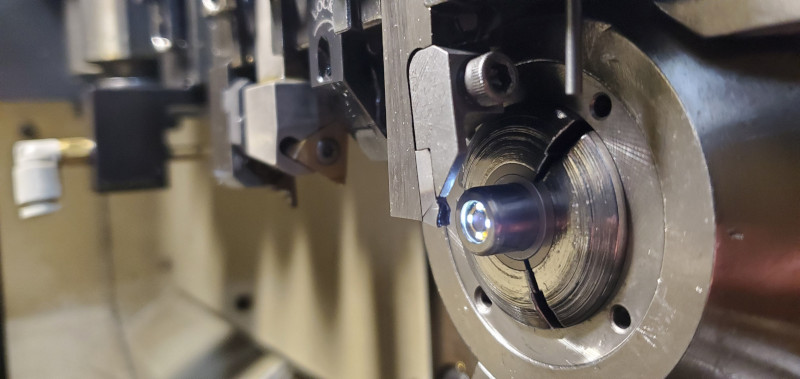

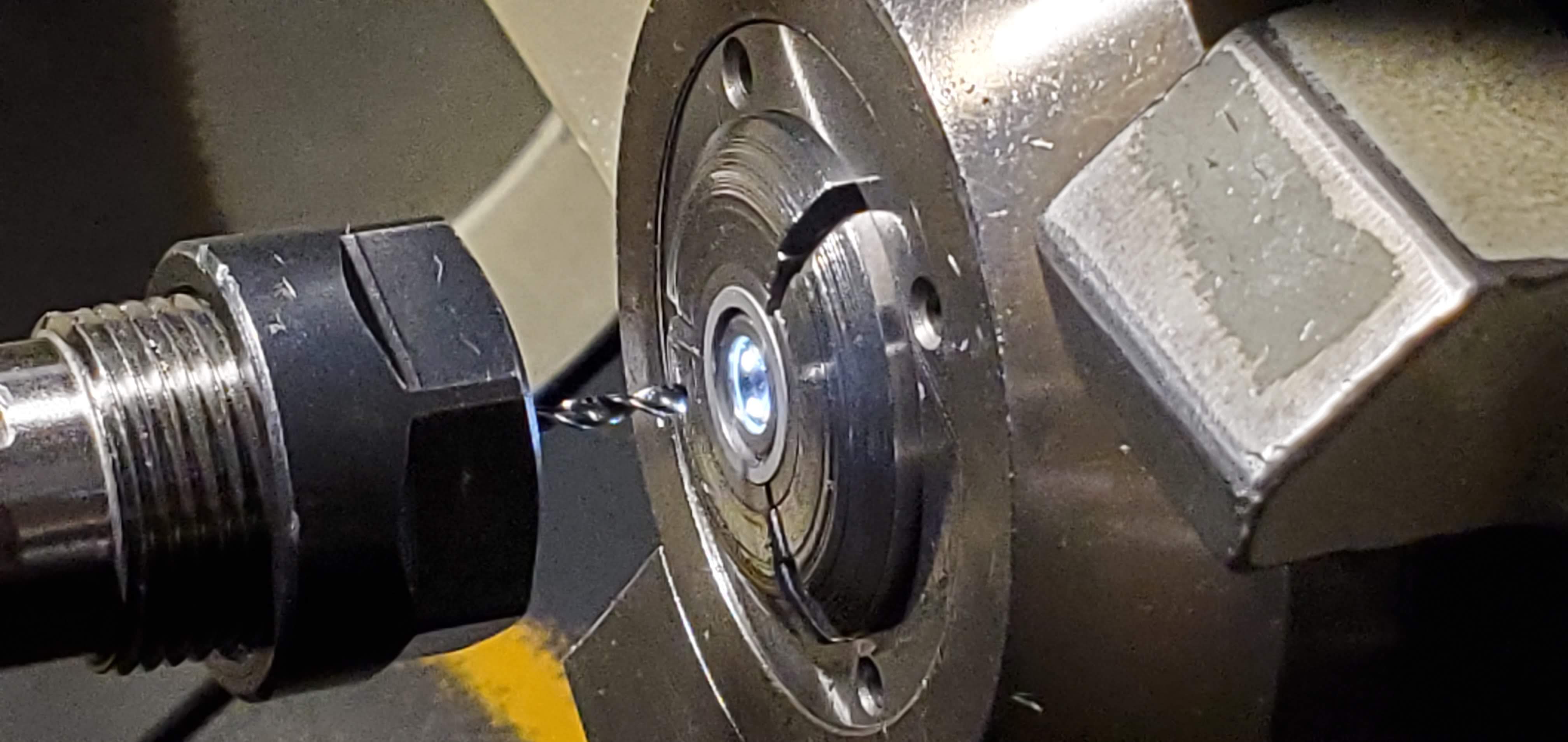

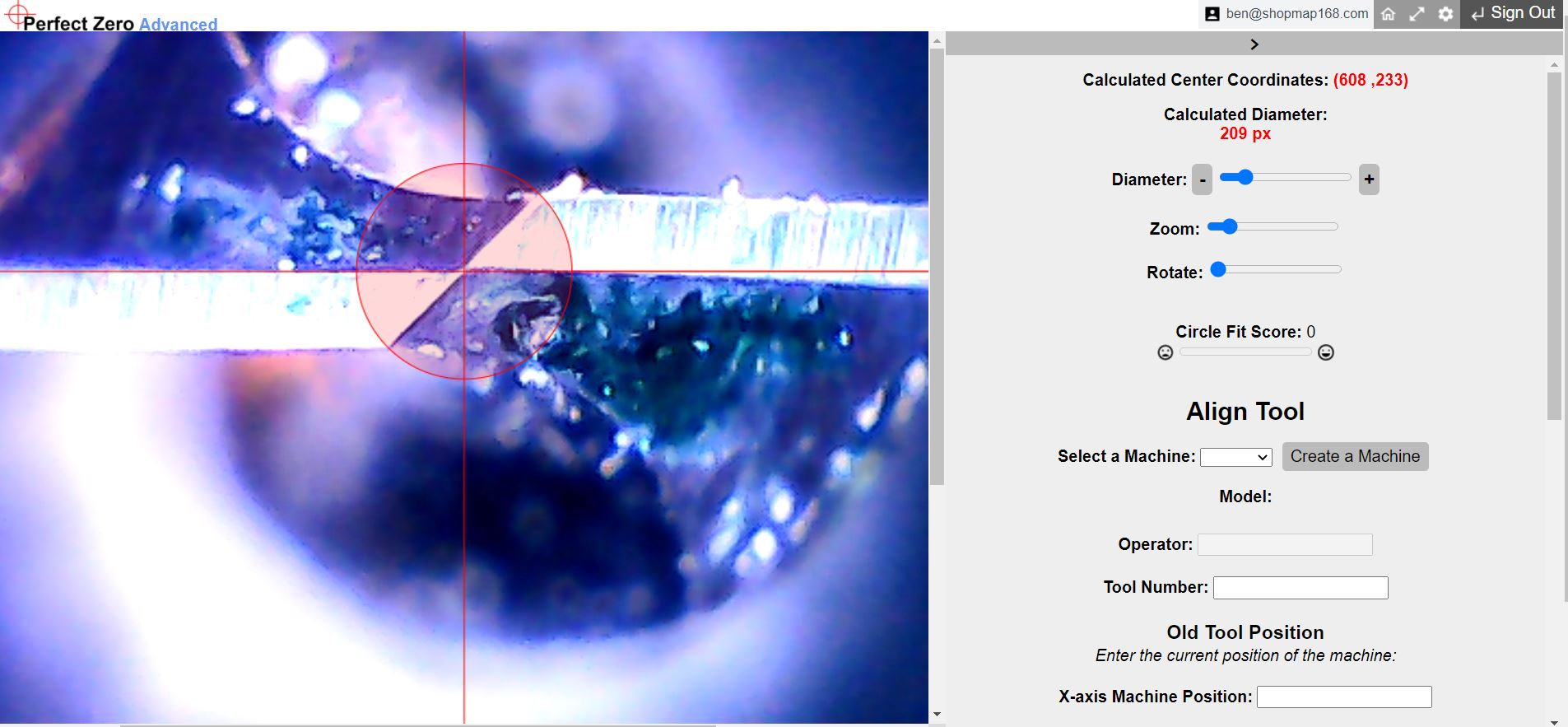

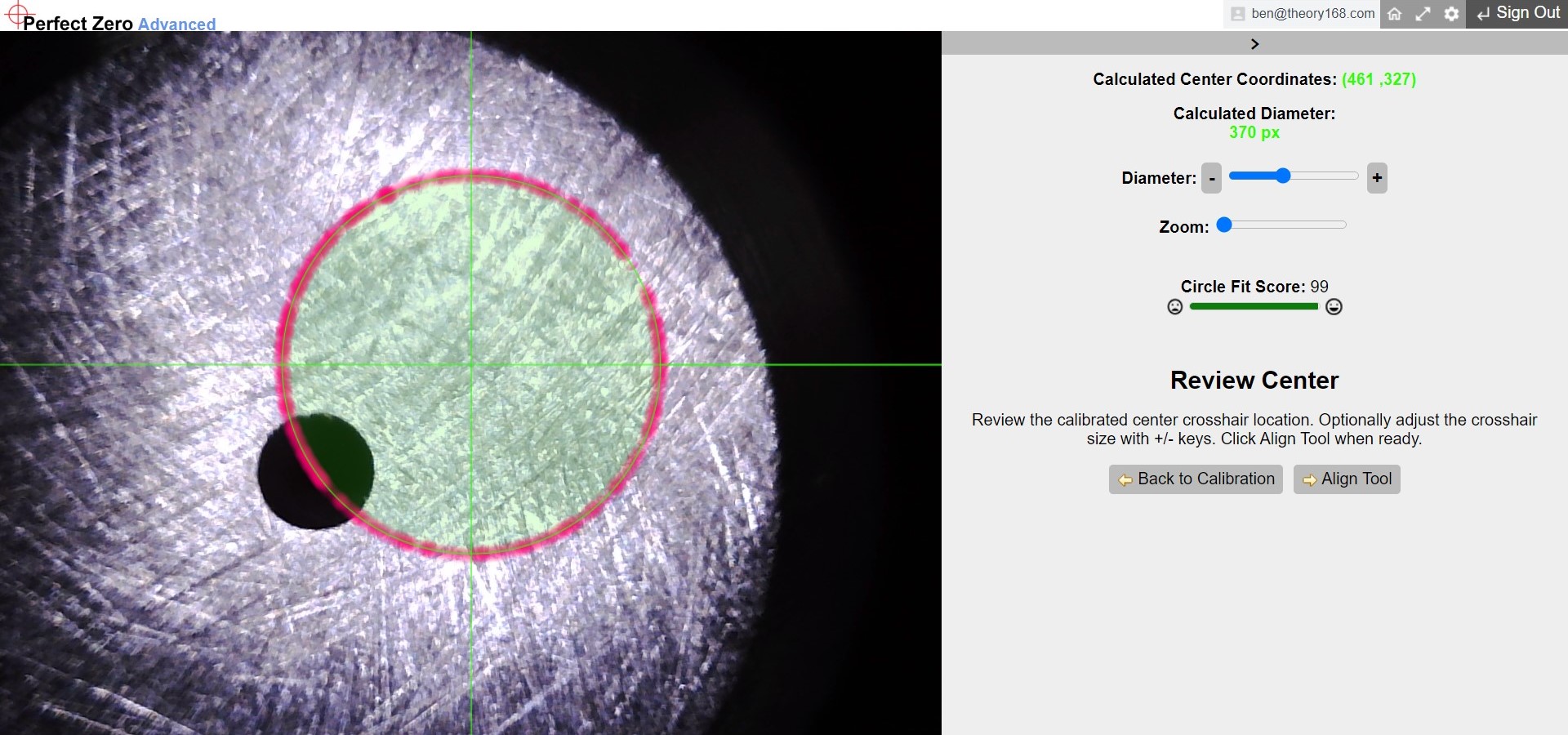

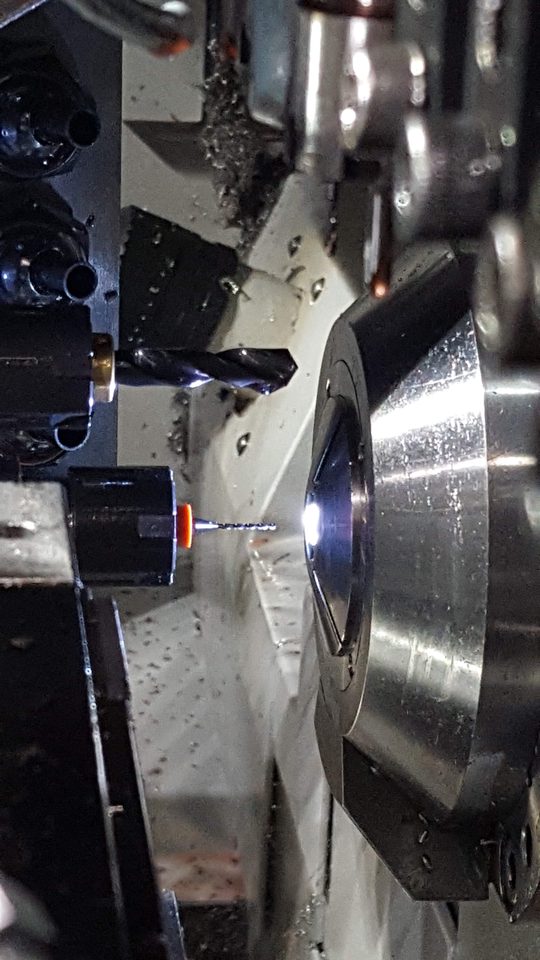

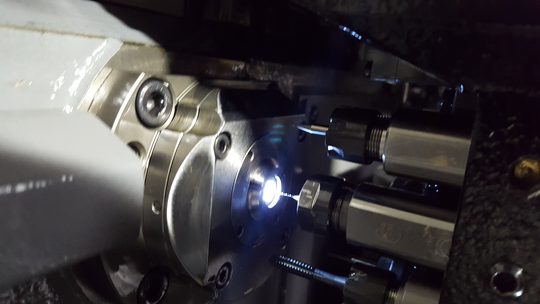

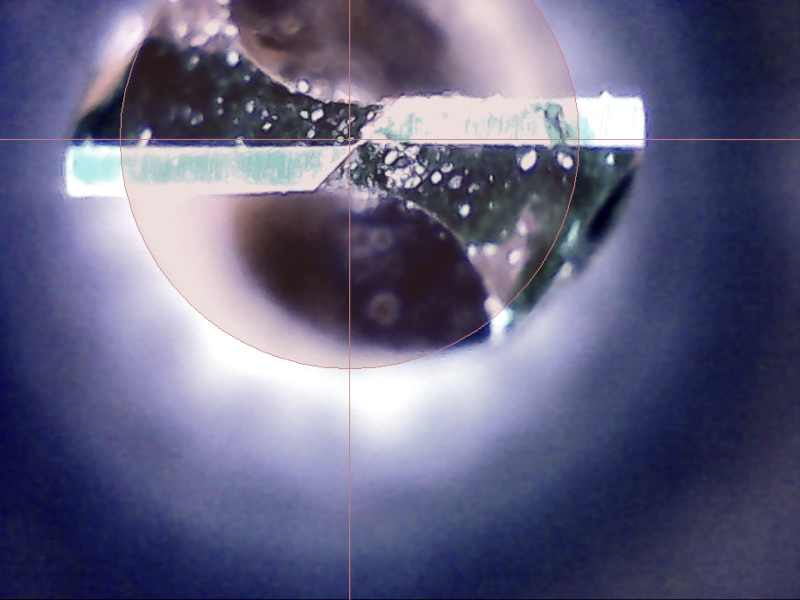

Use an industrial grade camera and state-of-the-art software to perfectly align your tools to the true centerline of your spindle. No more guesswork, trial and error, busted tools, indicators, probes, lasers, aka fuss.

Discover Perfect Zero®

- Positionally align tools in all CNC machines

- Intuitive to learn

- Faster setups

- Better tool life

- More accurate parts

- Simplifies process adherence

Problems Solved

- Align tools in the position they will be cutting the material

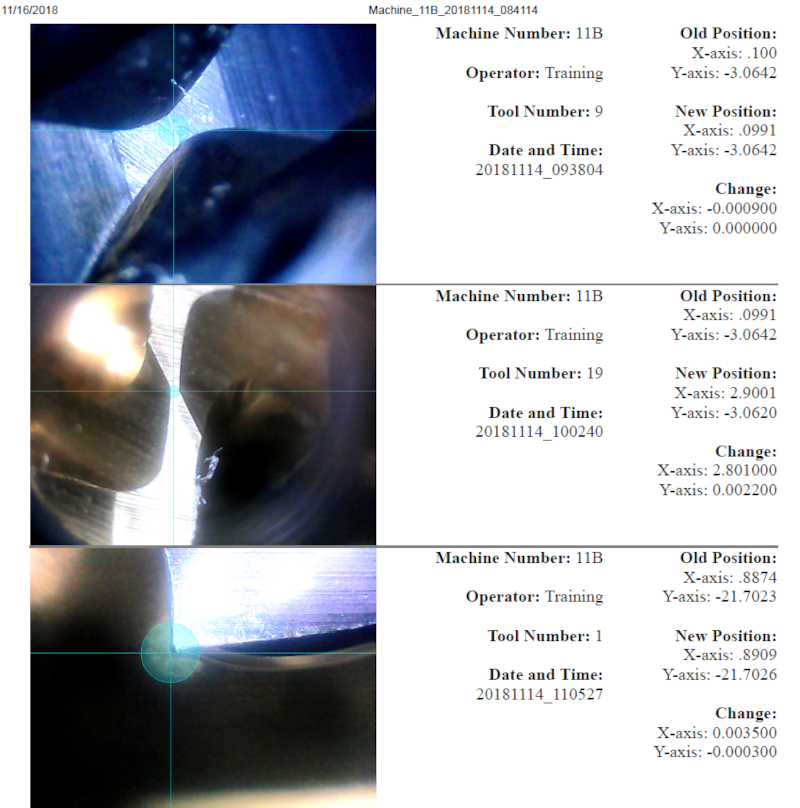

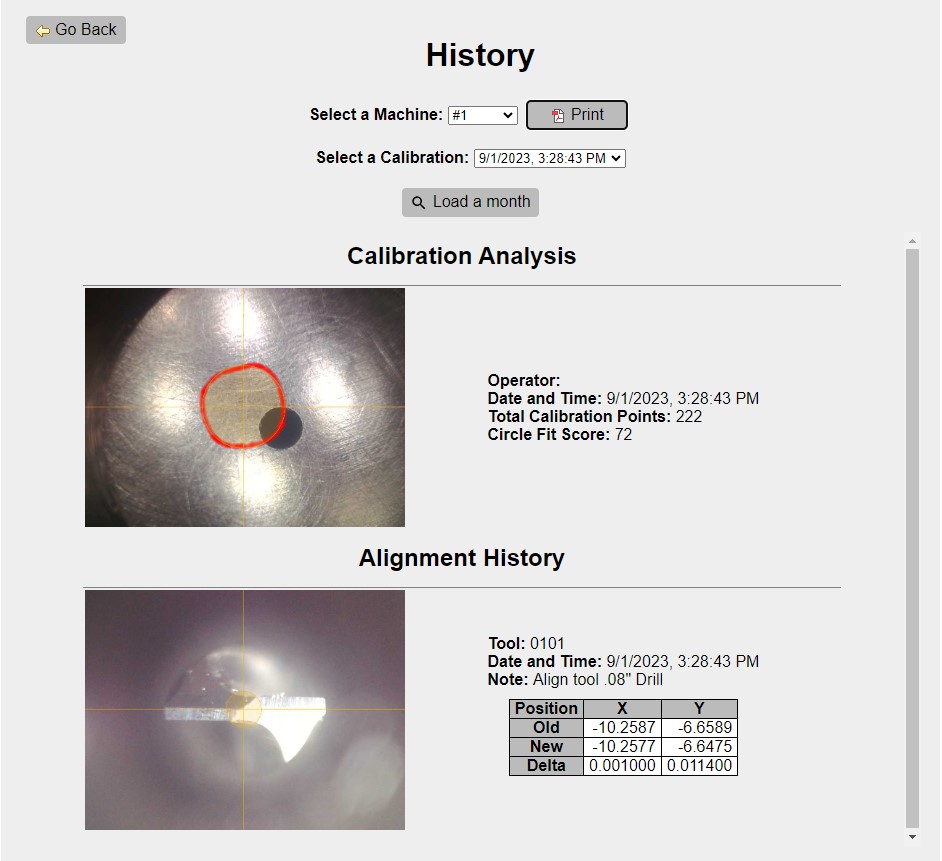

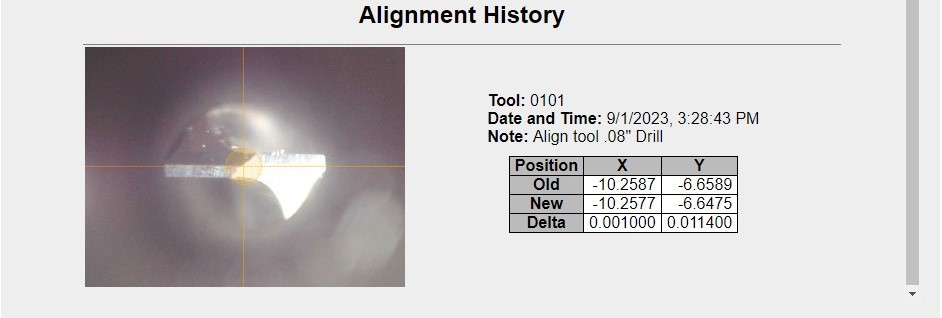

- Record alignments for post production analysis of operator, machine, or tool

- Ideal for saving grid shifts in the machine control

- Identify potential tool grind issues using high magnification

- Does not touch the tool

- Identify and measure spindle runout

It's this easy...

-

Place camera

-

Rotate around target

-

Determine center

⇩

-

Jog to tools

-

Align to center

-

Input positions

Problems with a spindle?

Setup taking forever?

Save yourself time and headaches with our proven, turn-key solution.

Testimonials

FAQ

What are the differences between the Web App and the Desktop App?

What are the computer requirements for the software?

Can I use the software offline?

How will I receive the software?

What comes with the camera?

Does the camera come with a warranty?

What is the repair/replacement process for the

camera?

What types of spindles are compatible with the

camera?

What types of machines are compatible with the

camera?

What size of machines are compatible with the camera?

What types of tools can be aligned?

What is the field of view and working distance of the camera? Is

the zoom or focus

adjustable?

Is the camera waterproof? How is it best cleaned of oil and

coolant?

Is the light adjustable on the camera?

Do you offer custom cameras?