Ultra Value

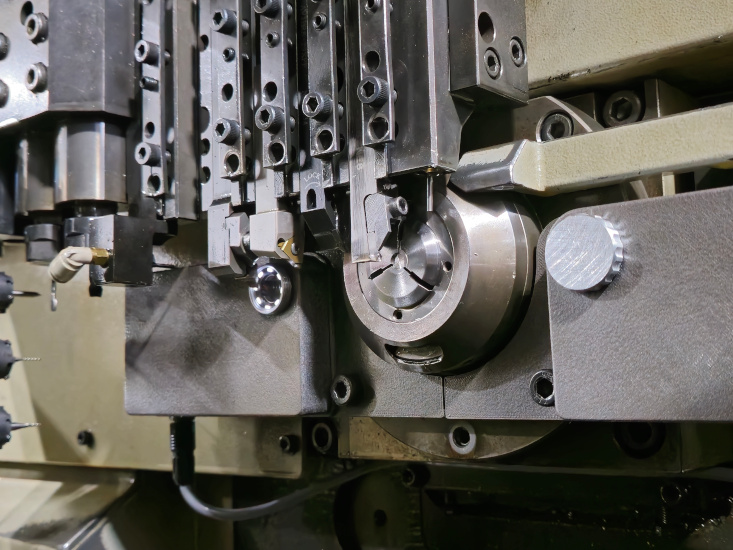

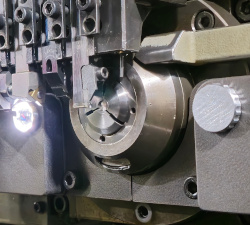

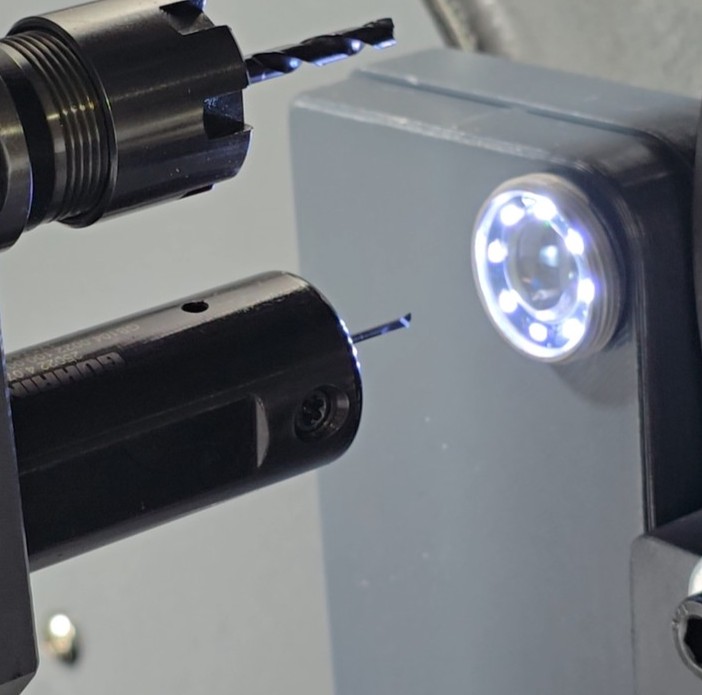

Perfect Zero® Ultra Swiss is a always-ready visual tool alignment solution — designed to align your Swiss tooling on demand with our most advanced cameras. It offers the same ease of use as our Perfect Zero guide bushing and collet-mounted cameras, but with one key advantage: Ultra Swiss remains installed in your machine at all times, streamlining your workflow and boosting productivity. Simply remove the protective cap, jog your tools in front of the built-in camera, and confirm or adjust positions in just seconds. It has no exterior moving parts to worry about when focusing on your tooling.

- Use the camera in an instant

- Built-in clearance to avoid collisions

- Easily align, set, and check tools

How it Works

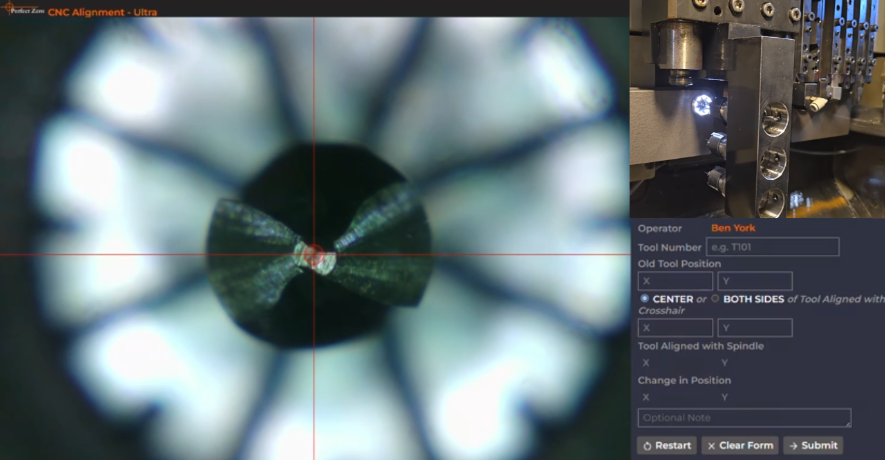

Operators can set tools within seconds — often without stopping production — then quickly resume making parts. The process is simple:

- Blow off any residual oil from the gang slide area

- Unscrew the IP67 high-pressure, oil-proof cap

- Jog a tool in front of the camera to align and set it

- Apply the offset shown in the software to the machine control

It's that quick!

Set smarter. Run longer.

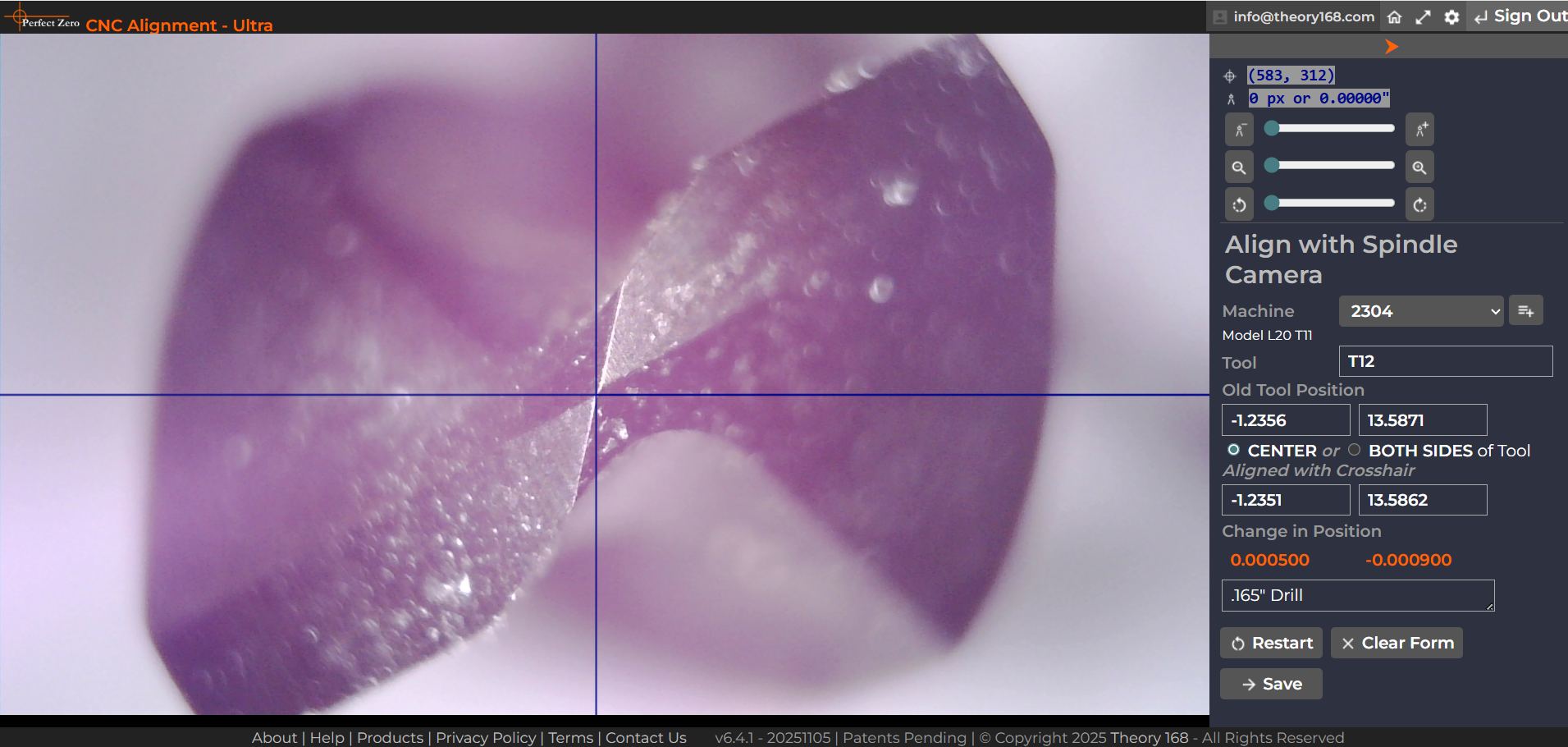

The Ultra Swiss camera system delivers precision tool alignment without touching off stock. Operators can visually confirm tool position, check for proper alignment, and inspect edge wear without removing the tool from the machine. Designed for speed, accuracy, and uninterrupted performance.

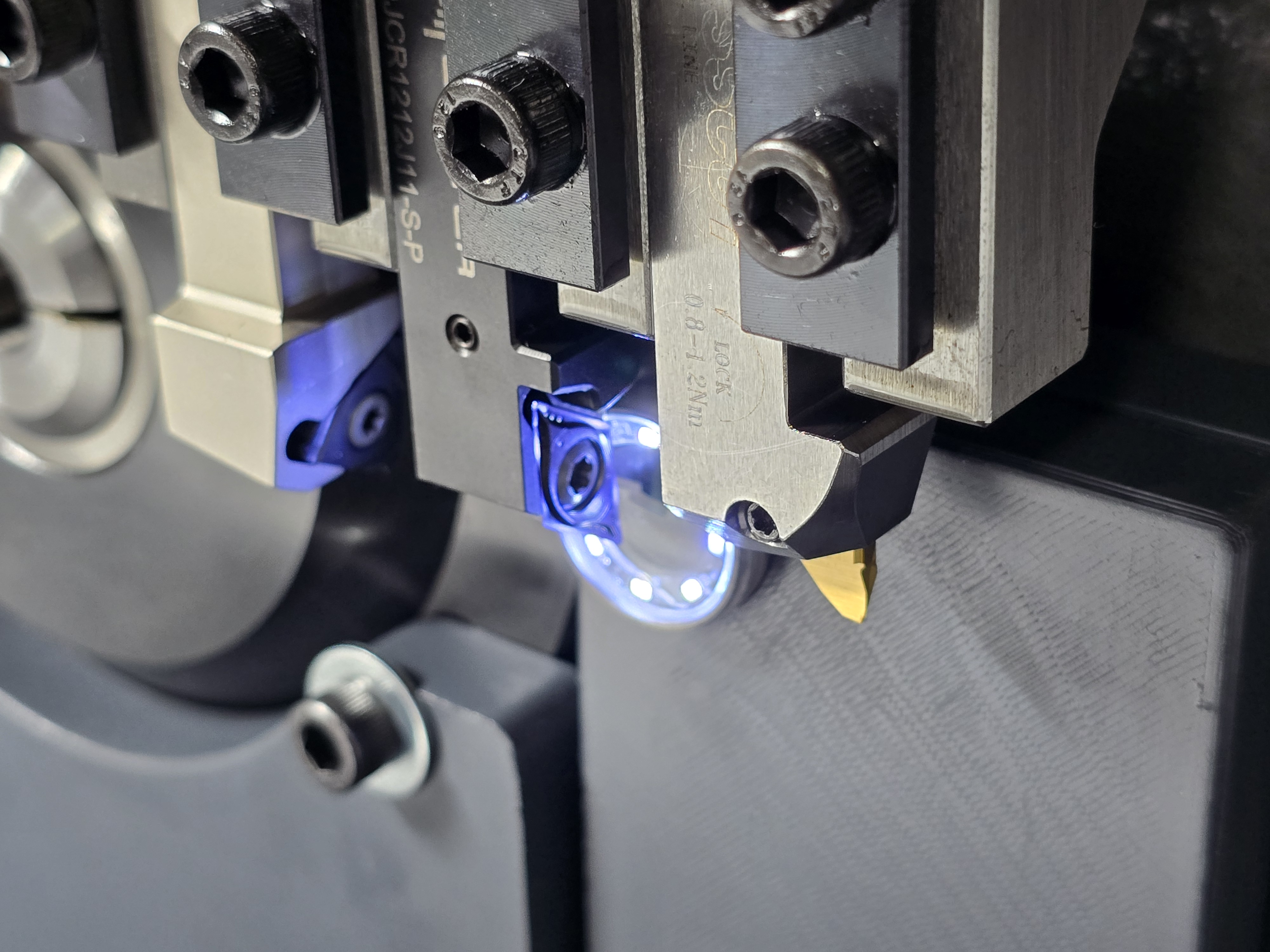

The camera captures the edge of the OD turning insert as it approaches the guide bushing centerline. Operators use this view to visually align the tool to machine zero.

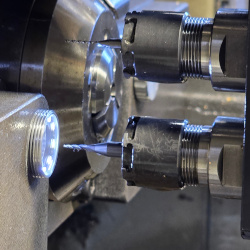

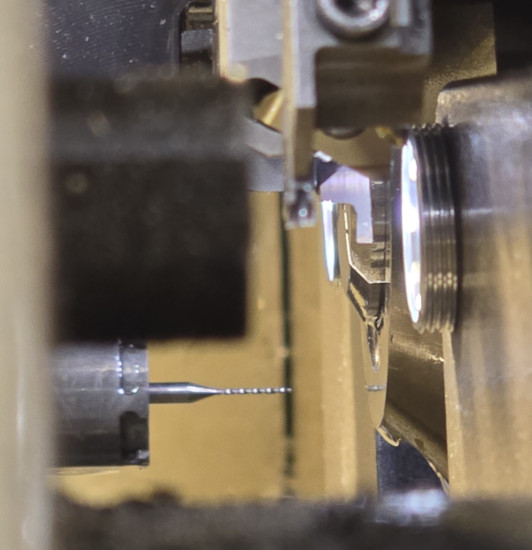

Cross drills are brought into view to verify alignment along both X and Y axes. Ultra simplifies setups, even for the most complex cross-working tool configurations.

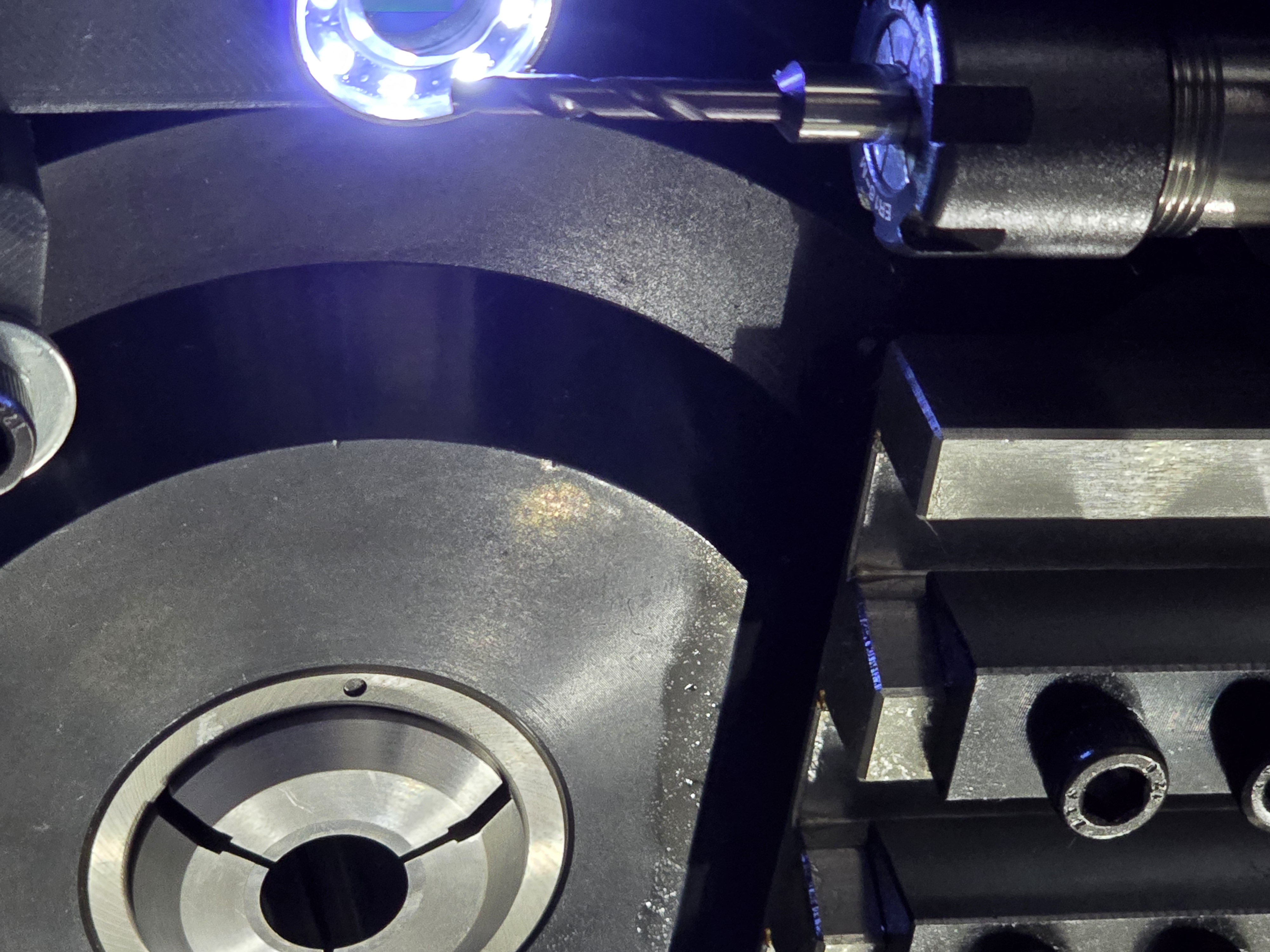

The boring bar is jogged into position and viewed at centerline. Verifying Y-axis centerline on a boring bar is not easy. Ultra provides a visual reference to confirm position relative to the part ID without physical contact.

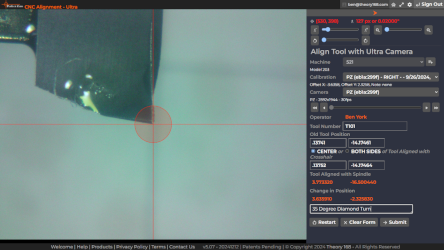

Live camera image is combined with the Ultra software interface to align tools precisely. Crosshairs overlay the tool for centerline verification, while the entered data captures tool number, side, and offset detail are all in one streamlined setup screen.

One Time Installation

- Mount the Perfect Zero Ultra Swiss to the face of the guide bushing using included hardware

- Align the unit to the gang slide using an indicator

- Connect the cable to the unit and route it to the backside of the machine

- Calibrate Ultra to the centerline of the guide bushing rotation

That's it. Your Perfect Zero Ultra Swiss is now ready for use.