The Reality of Alignment

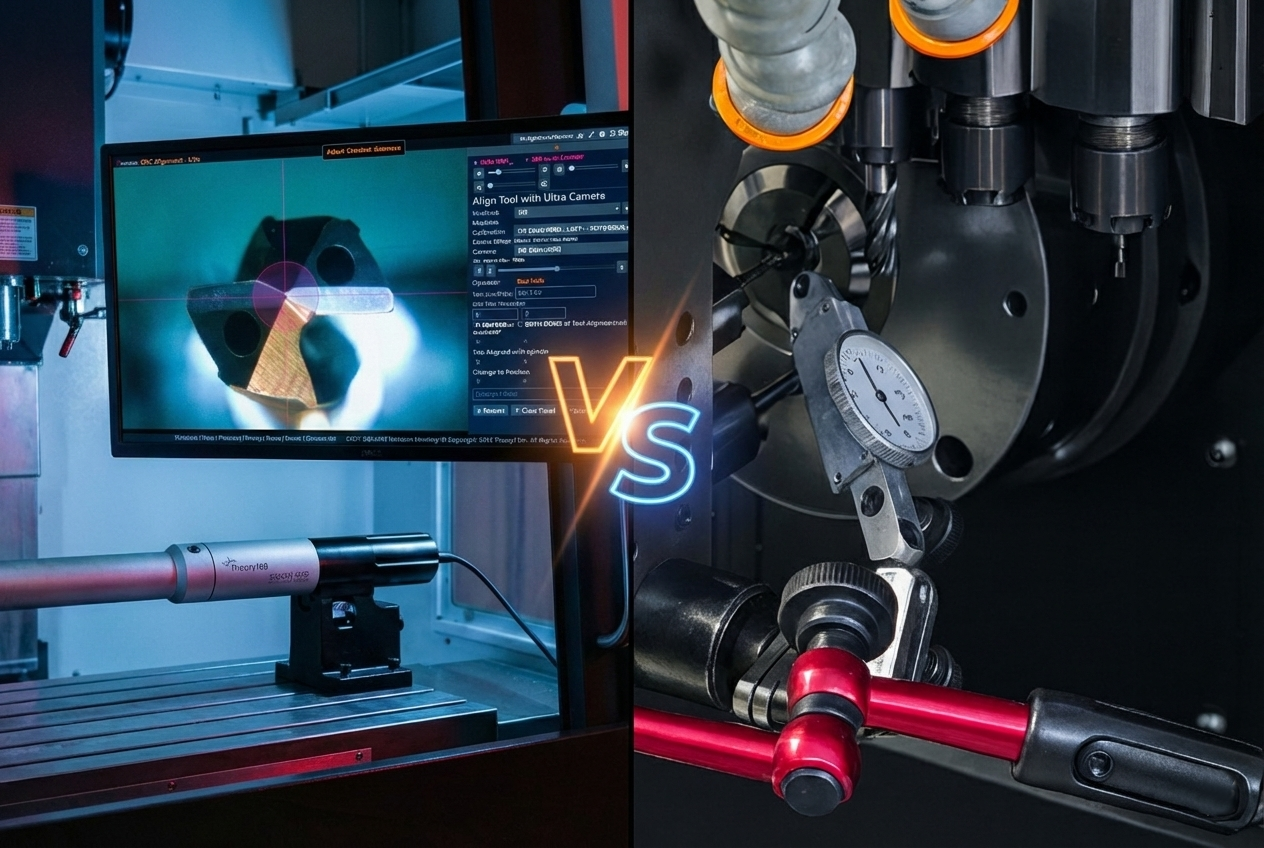

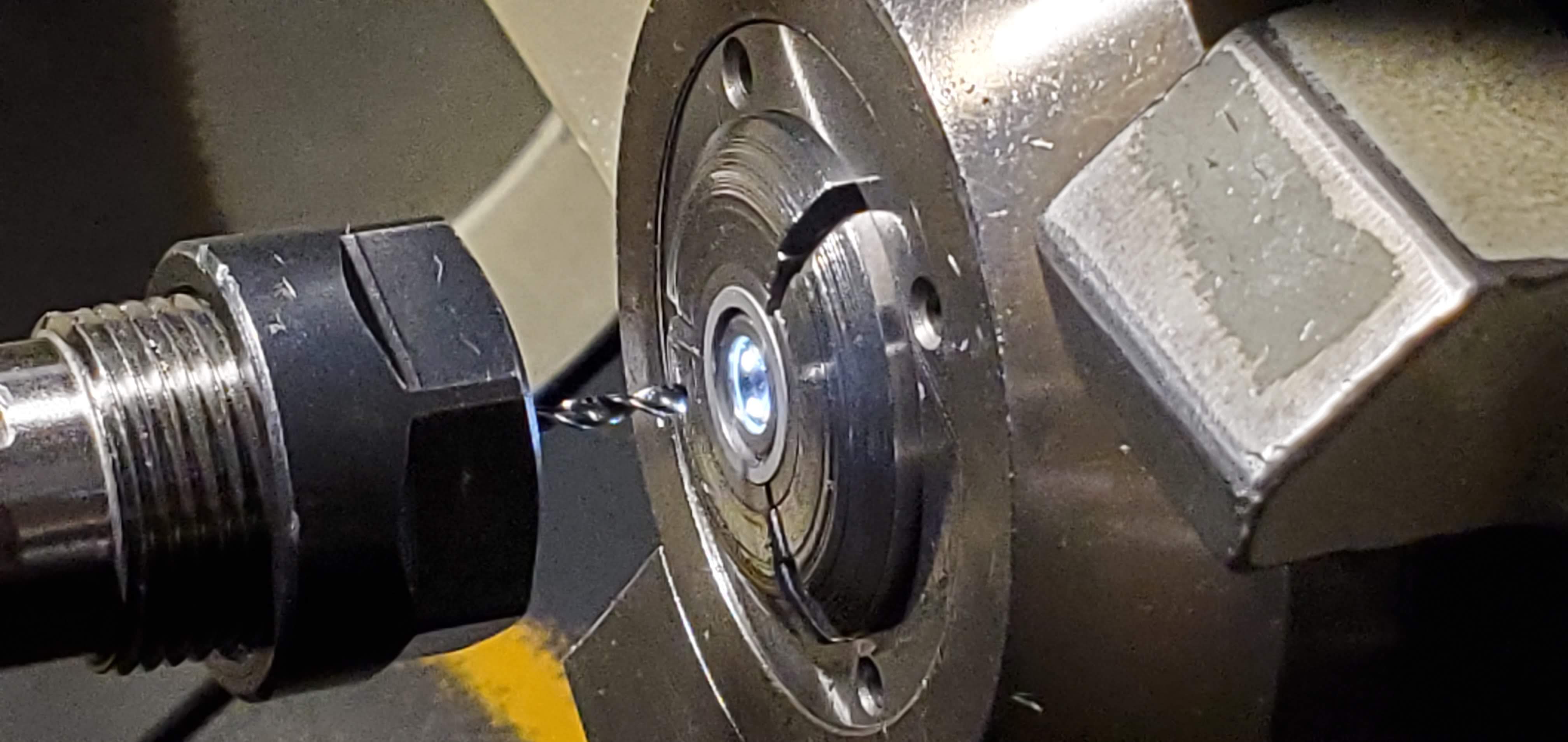

In precision machining, "close enough" isn't an option. For decades, the dial indicator has been the go-to tool for alignment. It is mechanically simple and the procedural logic is easy to grasp—although difficult to execute!

Let's be fair: a dial indicator excels at checking axis integrity and perpendicularity. However, as part tolerances tighten and the labor gap grows, it's right to question how the dial indicator stacks up against new-age alignment tools.

The Dial Indicator: Simple Tool, Complicated Process

On the surface, a dial indicator is straightforward. But in practice, it's anything but.

The "Transfer" Problem: An indicator doesn't easily find the center of rotation; it provides a transfer measurement. To align a guide bushing to a sub-spindle, and then the sub-spindle to the back of a tool holder, you are performing a daisy-chain of measurements and potentially stacking up errors at every link.

The Math Tax: Whether it's a grease-stained notepad or an Excel spreadsheet created 10 years ago, the operator is responsible for multi-step math. There is no way for this "tried and true" process to avoid this computational burden and the resulting risk of human error.

The Training Barrier: While a veteran might navigate these steps by memory, training a new operator on the nuances of reading a dial and executing the calculations is a steep, time-consuming climb.

Alignment Camera: Becoming the Eye of the Machine

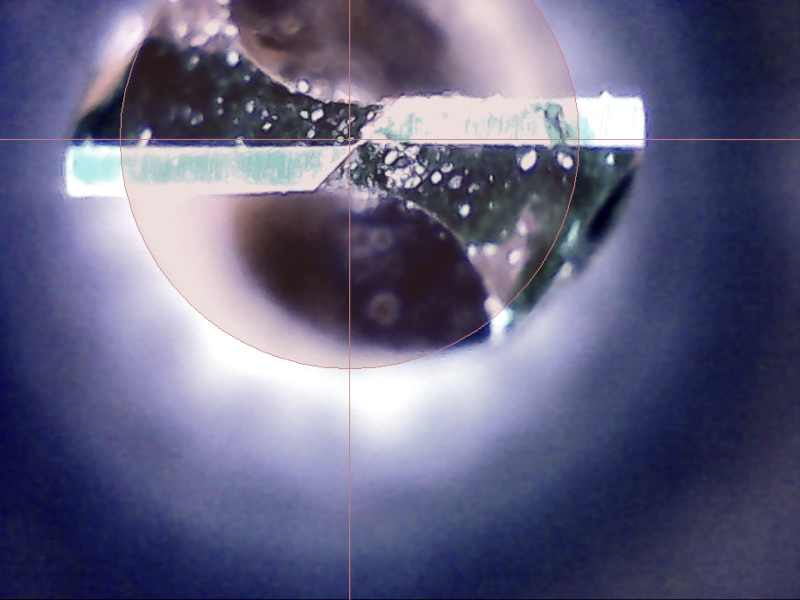

The Perfect Zero® approach shifts the perspective—literally. Instead of measuring around the tool, you are looking directly at the cutting edge from the perspective of the spindle.

True Center of Rotation Aligned with Cutting Edge: By placing the Perfect Zero® camera in the guide bushing, you can spin the bushing and quickly find the true center of rotation. For tool alignment, you aren't guessing based on the back of a tool holder; you are seeing the cutting edge in the exact position where the tool is mounted.

Intuitive Interface: Software handles the heavy lifting. Instead of manual calculations, the system provides step-by-step instructions and does the math for you. You aren't just an operator; you're the eye of the machine.

Universal Application: While indicators often struggle with anything that isn't a round ID tool, the Perfect Zero® camera allows you to see and align the actual cutting edge of any tool geometry—from standard inserts to variable pitch end mills.

At a Glance: Dial Indicator vs. Spindle Camera

| Feature | Dial Indicator (Traditional) | Spindle Camera (Visual) |

|---|---|---|

| Perspective | Daisy Chain: Measures surfaces around the tool to the sub-spindle, and then from sub to main. | Eye of the Machine: Direct view of the cutting edge from the spindle's perspective. |

| Center of Rotation | Difficult: Requires multiple steps to find—and bi-focals to read the dial. | Direct: Align to the true center by spinning the system in the guide bushing. |

| Mathematics | Manual: Requires calculators, paper, or spreadsheets. High risk of error. | Automated: Software handles all calculations instantly. |

| Ease of Use | Expert-Level: Relies on a "tried and true" process known by veterans. | Intuitive: Step-by-step software instructions guide the operator. |

| Training Time | High: Hard to teach and takes years of experience to master. | Low: Fast learning curve; easy for operators-in-training to follow. |

| Tool Versatility | Limited: Primarily for ID tools or round holders. | Universal: Works for any tool geometry, including inserts or variable pitch end mills. Even super fragile micro drills. |

| Best Used For | Checking if machine axes are square. | Aligning precision tools to the spindle centerline. |

The Bottom Line

The dial indicator is a classic for a reason, but it demands a level of manual calculation and "feel" that is hard to replicate and standardize across teams and shifts. By adopting a system that eliminates manual math and focuses on the spindle's center of rotation and the tool's cutting edge, shops can reduce downtime and scrap, save money on tools, and upgrade their capability in 2026.